“I have way too much space!” — said no professional chef, ever.

There’s a reason for that: In a commercial kitchen, every bit of space needs to earn its keep. So whether you’re starting with 75 square feet or 750, you don’t want an inch to be wasted. You can’t afford for equipment to sit idle, but you also need to make sure you have the right tools for every job.

What’s the solution? We have some strategies to making the most of your equipment and space to maximize efficiency in any kitchen, no matter the size.

1. Observe your kitchen staff.

During a busy shift, who’s colliding with who? Who’s short on prep space? Where are the busiest lanes, and can they be moved away from cooks doing precise or delicate work?

2. Deploy an immersion blender.

When you’re short on space but you need a versatile blender, the answer is the BigRigTM family of commercial immersion blenders. With the most powerful motor in its class, a variable speed dial and an ergonomic handle, the BigRigTM is designed for continuous use all around the kitchen. The stainless steel shaft is removable and dishwasher-safe. Store immersion blenders on a hook or shelf when not in use.

3. Think vertically.

If counter space is at a premium, look up. Vertical storage, such as racks for cookware and utensils, can maximize storage space. Some commercial kitchen equipment lends itself well to wall mounting, such as the HMD300 Wall-Mount Single-Spindle Mixer. It’s always right there when you need it for blending milkshakes, mixing batters, even frothing milk with the optional 928 agitator. The cup rest allows hands-free operation, giving busy cooks a break.

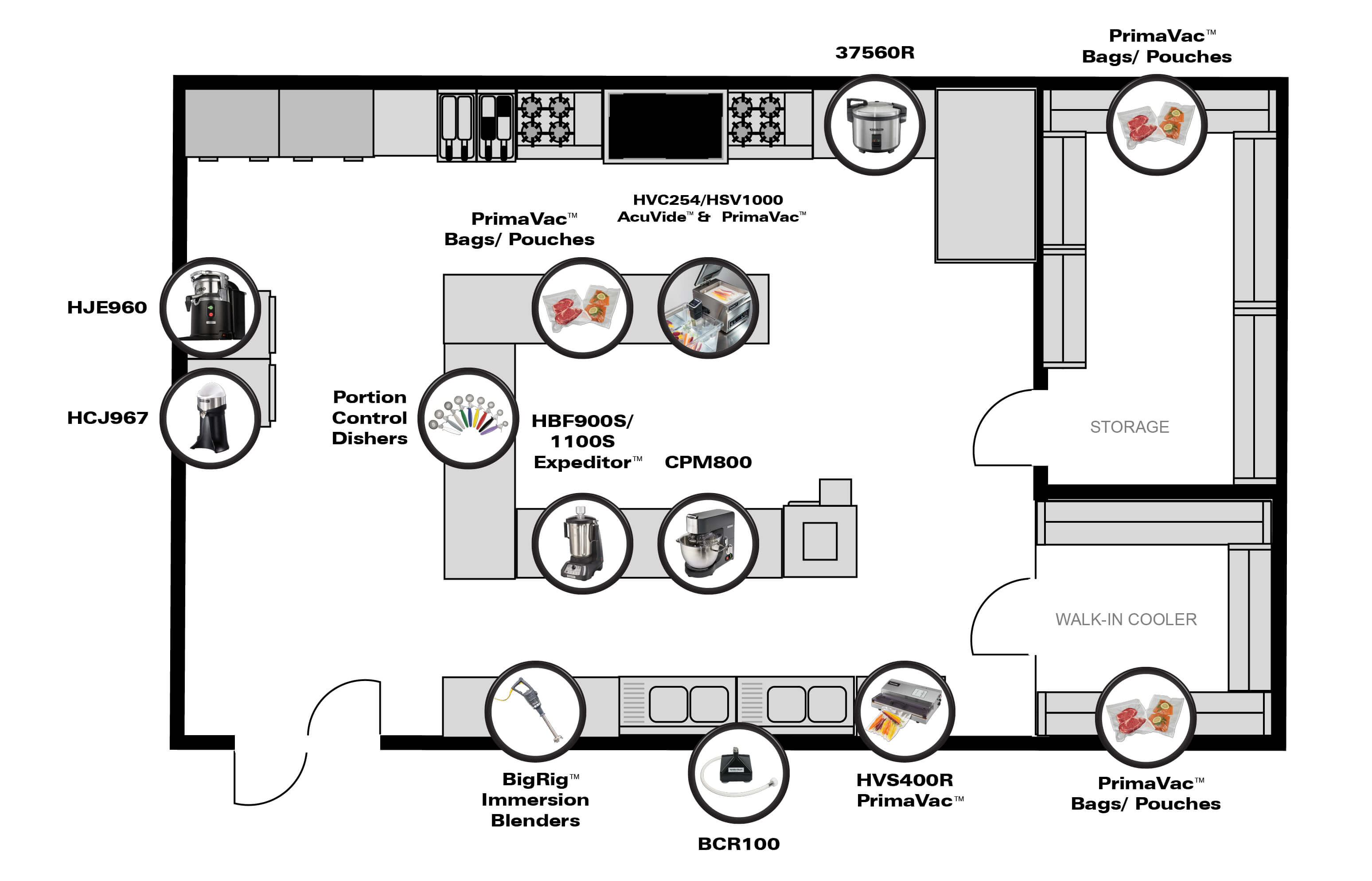

Here’s one proposed kitchen layout using Hamilton Beach Commercial equipment.

4. Prioritize delivery.

When updating an older kitchen or designing a new one, think about how to accommodate delivery and takeout orders. “Some fast-casual concepts are adding a second assembly/turn-out station that's operated solely for mobile ordering and delivery services during peak hours—lunch and dinner rushes,” James Feustel, account manager and designer with Singer Equipment, tells Restaurant Business. “Other concepts have started from scratch and have redesigned the cook/assembly/expo process to make it more efficient.”

5. Consider multi-use appliances.

Whether you’re looking at the pieces you already have or investing in some new commercial kitchen equipment, ask yourself: What else can it do? For instance:

- A commercial stand mixer has many unexpected uses beyond kneading dough and mixing batters: use it to shred cooked meats, flavor butter, make guacamole and more.

- A commercial rice cooker lends itself well to all kinds of cooked grains and breakfast dishes: oatmeal, porridge, grits and quinoa, just to name a few.

- An immersion blender (hello again, BigRigTM) can blend soups and sauces in the pot, salsas at the prep station, even whipped cream for desserts.

6. Don’t neglect the smallwares.

Often overlooked in commercial kitchen design, small tools like knives, cutting boards and turners are essential for efficiency. Make sure you have enough of everything, and identify the best places to store them so they’re easy to grab on the fly. Hamilton Beach Commercial dishers have a cult following among chefs for their ergonomic design, tough construction and rainbow-hued handles.

7. Use a commercial vacuum sealer to preserve and store food.

The PrimaVac™ commercial vacuum sealer makes room for itself by allowing prep cooks to easily store, preserve, and season dishes. Instead of cluttering the walk-in with messy tubs, marinate meat and poultry in vacuum-sealed pouches. Wash and vacuum-seal produce as soon as it’s delivered, and it stays fresher longer. Some of our customers tell us that a PrimaVac™ sealer can pay for itself in just 5 to 7 weeks, as they’re seeing $200-$300 savings per week in spoilage/waste prevention. Just be sure to train kitchen staff in safe food handling practices when using vacuum packaging.

8. Don’t waste money on cheap equipment.

What’s the weakest link in a restaurant kitchen? That broken piece of equipment over there in the corner. You’d be surprised by how many operators, in an effort to cut costs, buy inexpensive pieces designed for home kitchens. Then, the motor burns out or overheats because it can’t handle the demands of professional use.

All Hamilton Beach Commercial kitchen equipment is relentlessly tested in real-world conditions and built to last. In the rare instance that something breaks, our Express Care Warranty program (for U.S. customers and qualifying products) can ship a replacement product to your location to minimize downtime.

Discover Hamilton Beach Commercial’s full line of foodservice equipment and schedule a demo today!