If you’ve ever had a high-performance blender conk out after many years of hard use, the culprit was probably the brushes.

“Brushes?” you might ask. “I didn’t know my blender had brushes.” Most people don’t, because busy restaurant operators never think about the innards of their blenders. But we do. For eight years, we’ve been thinking about how to design a better blender motor that doesn’t die when the brush wears out — and now we have it. It’s called Endura™ Motor Technology.

What are motor brushes, anyway?

Despite its name, a motor brush looks nothing like the object you use to smooth your hair or clean your teeth. It’s actually a block of carbon that serves to conduct electricity to a motor. Not just a blender motor, either — virtually every electric motor in restaurant equipment contains brushes.

Brushes are kind of like brake pads: Because of the friction they experience as the motor shaft turns, they wear out over time. Once they’re rubbed down to the base, the motor stops working. Most people don’t replace the brush, because it’s more cost-effective to simply replace the motor or the entire blender.

Here at Hamilton Beach Commercial, our engineers are obsessed with making our products last as long as they possibly can. (That’s why you’ll often see one of our 1960s spindle mixers still doing its thing behind an old-fashioned lunch counter.) But the brushes kept getting in the way… so we got rid of them entirely.

Introducing Endura™ Motor Technology

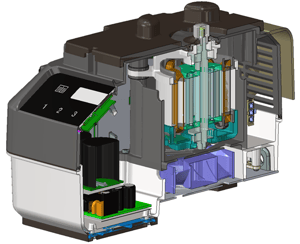

A brushless motor contains a computerized controller and magnets that spin without friction. It’s not new technology, but only recently have these motors become advanced enough to provide the level of performance demanded by high speed blending. Now that it is ready to meet our rigorous standards for performance, we’ve used Endura™ Motor Technology to power the new Quantum™ 950 high-performance blender. Why is this technology better?

- It’s incredibly durable. Endura™ Motor Technology can last a really, really long time — up to 2.5 times longer than a conventional motor. The Quantum™ 950 has the best motor warranty in the industry: 7 years. If the motor on your blender fails within 7 years, we’ll replace it.

- It’s quieter. With less fan noise and no brush noise, Endura™ Motor Technology is noticeably quieter than a universal motor.

- It’s more efficient. Endura™ Motor Technology is 50 percent more efficient than a conventional motor, so it needs less electricity to deliver powerful, consistent blending. Think about incandescent bulbs vs. LEDs — you get the same amount of light with less energy usage and much longer product life.

- It’s cooler. Endura™ Motor Technology generates much less heat than a conventional motor, reducing the risk of overheating. The fan operates independently of the motor, only coming on when it’s needed (which extends its life, as well).

Learn more about what the Quantum™ 950 can do for your business.